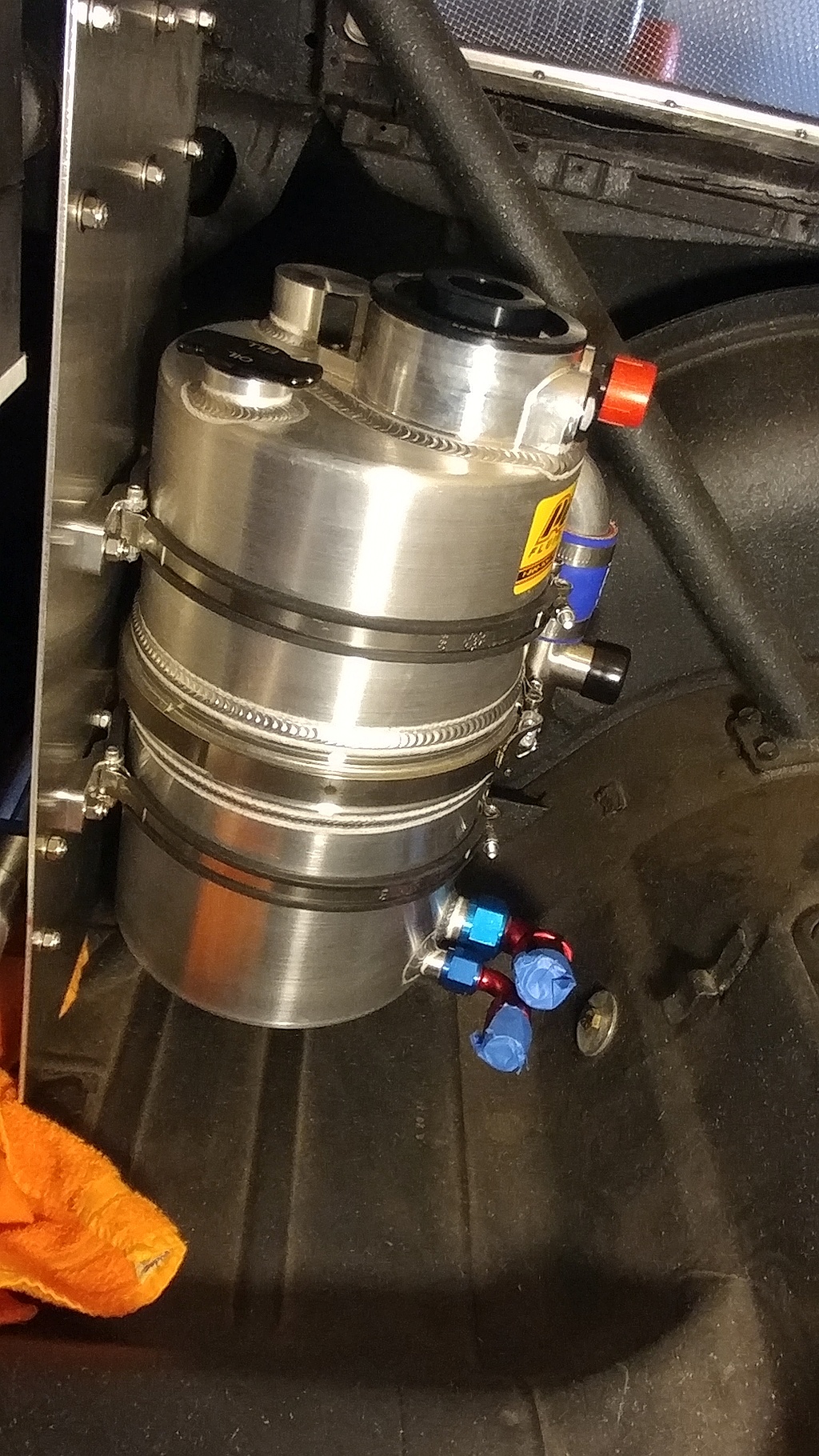

Peterson Dry Sump Tank Mounting

After getting an oil pan sorted out (SBF Dry Sump Pan) It was onto fitting an oil tank. I had picked up an oval-ish shaped tank that I was going to mount in the 1965 Mustangs battery box area in the front of the car. After jugging dimensions and looking at a dozen or so tanks, even sketching up one to fabricate I finally came to the conclusion that without a lot of fender cutting and related inner body work I would be better to mount the tank in the rear of the passenger side of the car.

This presented it's own set of options but when all done seemed like the best way to go. My car has the standard Autopower Roll Bar that is common in many early Mustangs. That gave me an idea on how to make a mounting plate and add a nice panel to mount a round and LARGE Peterson Fluid tank. Most of the parts are easy to get, but you will have to do some welding on the cross bar for the lower part of the panels mounting.

Metal tubing was standard thickish walled stainless that I picked up from Online Metals while they had a sale going on, as well as the bulkhead panels aluminum. The rest of the parts were from various suppliers (some listed below).

You sizes may vary a bit so check before ordering anything below. This is an expensive way to do it, so do modify based on budget. The Tiger clamps are expensive, but when all said and done it looks great.

System Parts

Stainless T-304/304L Seamless Tube 1.75" x 0.12" x 1.51" (I ordered 48" and trimmed it to fit)

Aluminum Sheet 12"x24"x0.125"

Ridetech Passenger and Driver Tiger Clamp these also get an OUCH on price (Passenger, Driver)

QTY 6 - Joe's Racing Tank Mounts 1.75" Bar. Amazon, Summit and Jegs all about the same. I went overkill and likely

Longer Hardware for tank mounts, might be 1/4"-28 Thread Size, 2-1/4" Long (DOUBLE CHECK LENGTH)

4 might be fine but figured I'm going to ensure it's a rigid mount.

Peterson Fluild Systems Mounting Brackets - 08-0101 Tank Mounting Brackets (kit of 2) (Amazon, Jegs)

Peterson Fluid Dry Sump Tank 08-9016 - 4 Gal. With Internal Filter (Jegs, be ready for the price!)

Various 1/4" lock nuts, washers. And 4 5/16" nuts, bolts, washers, etc.

Read on and see the photos of the install below

Back to Dry Sump Project Main