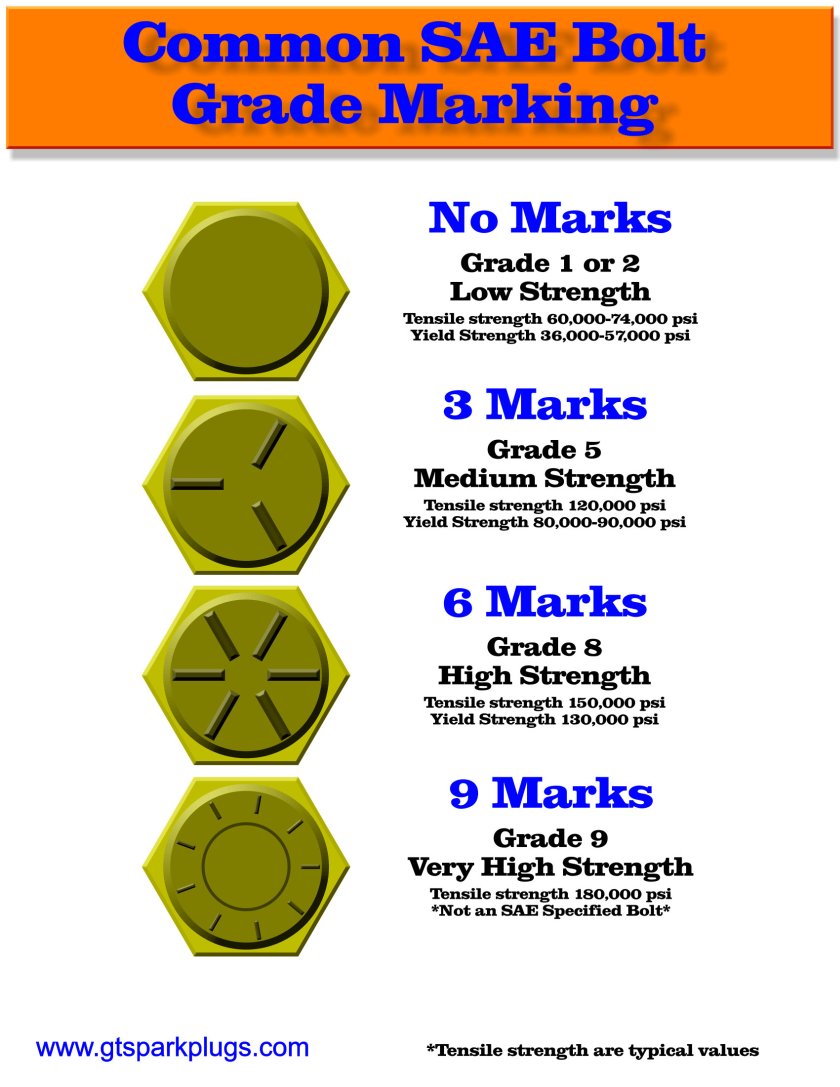

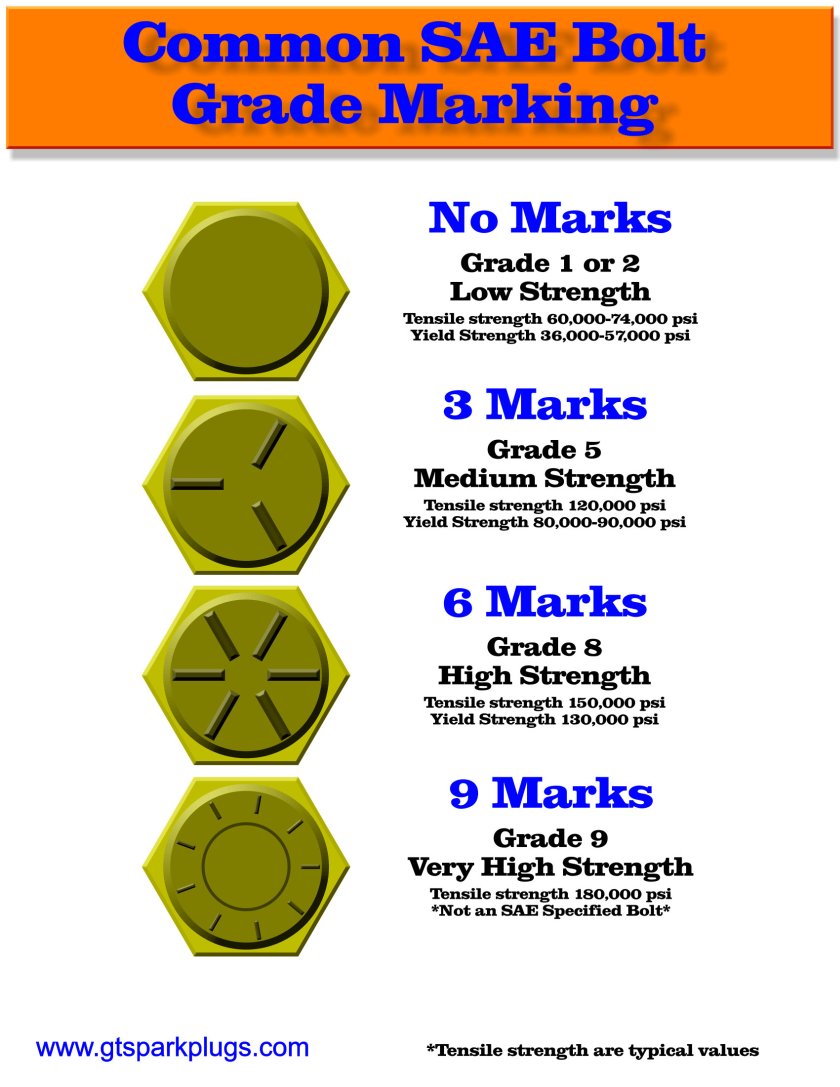

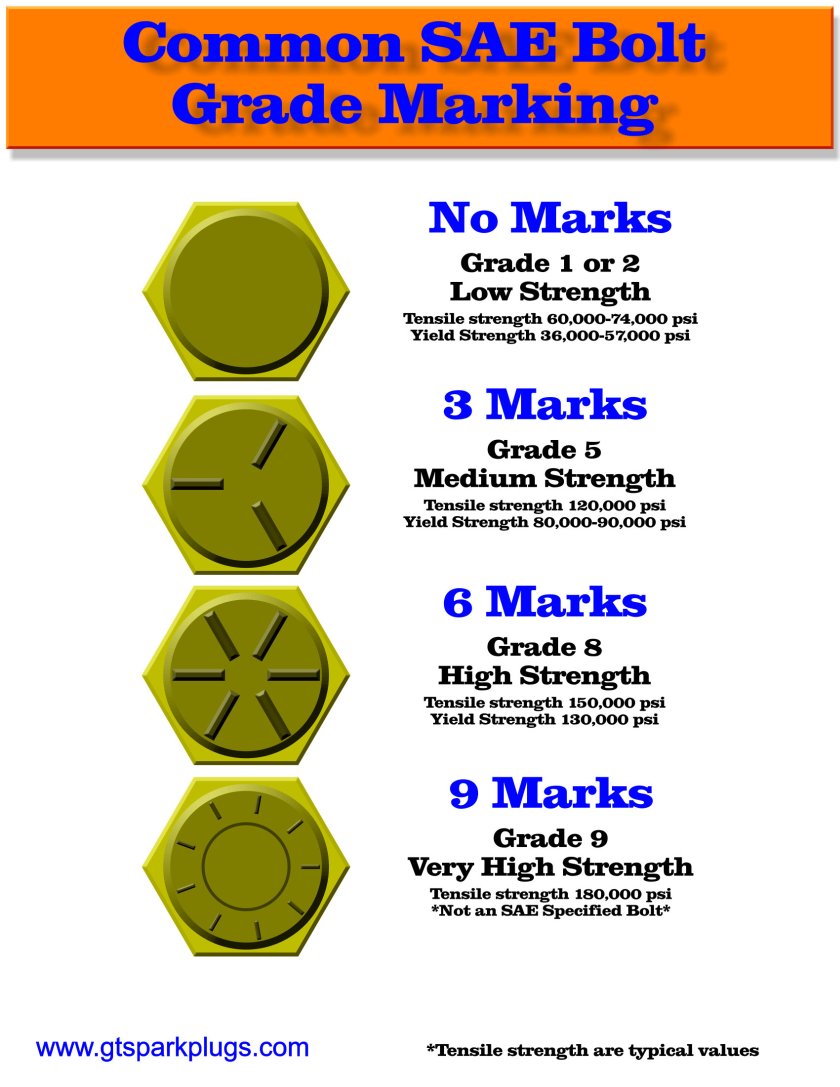

Simple EZ Read Bolt Grade Markings

This is the start of a simple page for common bolt head markings. This is again in the "EZ Read" format so those that are tired of looking at blurry and fuzzy charts can quickly determine the grade of bolts. This will be a work in progress as I get more time I'll add more then the SAE Bolt Marking for Imperial which are different for Metric. So if you are in need of a quick reference to bolt head markings look at the large images below. Note it's pretty easy to remember the bolt markings once you see them.

If you want a painfully complete document on strength of bolts, different grades, SAE, metric, etc. look no further then to the FASTENALL PDF Document. This has enough information for any engineer! It's likely derived from the many SAE specifications that exits.

My couple of turns on Bolts -

I use almost only GRADE 8 bolts. Their are a couple of reasons for this, the first one is that they are plenty strong and generally overkill for most of what I use them for so that is good. The second reason is that having a nut and bolt collection of multiple grade bolts (8, 5, etc.) is not practical unless you have a lot of storage space. The cost of grade 5 vs grade 8 is not much, so just step it up and get the better bolt. Grade 1 and 2 should be used for non-critical applications like holding on the the glove box door, etc. Grade 9 is NOT an SAE specification and is more a manufacturers indication of a stronger bolt then Grade 8. For Grade 9 bolts it important to view manufacturers specifications.

CAUTION OPINION AHEAD

Some auto/racing books and other sources have mentioned that Grade 8 bolts are 'Brittle'. I think this is BS. While they use the term 'Brittle' I think the term might be misused. Grade 8 bolts may not be as 'flexible', or 'ductile' as a Grade 5 bolt but I would hardly ever think of them as brittle. Use the right size bolt and you should not have any trouble with 'brittle' bolts.

That all being said I use Grade 8 bolts mostly everywhere except for specialty fasteners. Lastly get your hardware from a reputable place, some places sell import hardware that may not be as stringently tested or manufactured. And for anything of structural importance I would steer away from bolts without markings (hardware store, etc)

Stainless Bolts

Typical Stainless bolts are not as strong as regular steel bolts. I would consider strength under a Grade 5 rated bolt if that. They have some different properties that makes them nice and not so nice at the same time. The good is that they don't rust, the look nice, etc. The Bad is that they are not as strong AND if you are trying to use stainless bolts with stainless nuts you may run into galling when you tighten thing up. Sometimes lubrication will help, sometimes not. This is not a problem with steel (zinc chromate) plated bolts since the plating acts as a lubrication of sorts.

Odds and ends

You will also find some odd grade bolts and markings, I'm only covering the more commonly used ones. Poke around on the web, search for it then click images and you will see many pictures showing AN and Various markings. That's likely how you found this page!