CNC Master Cylinder Rebuild

The Ripper Mustang uses 2 CNC master cylinder and after sitting for a number of years I figured it might be time to

freshen up a couple of spares that I got from eBay. The model that I have is CNC Brakes 702 with filler cap. These are

nicely made master with a stainless sleeve. The master I picked up were in very nice condition, 2 were unused, and 1

was lightly used. So after inspecting them all I decided to embark on another DIY rebuild project.

The one that I rebuilt was the Model 702F-3/4 with EZ-Fill cover. These masters are available in many different

bores, from 5/8" to 1 1/16" models. If you need to get one of the Model 702 available at a fair price on Amazon as well

as a few other race parts places. It's not as common as the Wilwood or Tilton masters but still a very good choice.

And CNC is not what you think, it stands for Chuck Neil Corp.

Needed Tool and Supplies

Snap Ring Pliers

Small Screwdriver

Brake fluid

Parts Needed (3/4" 702 Master)

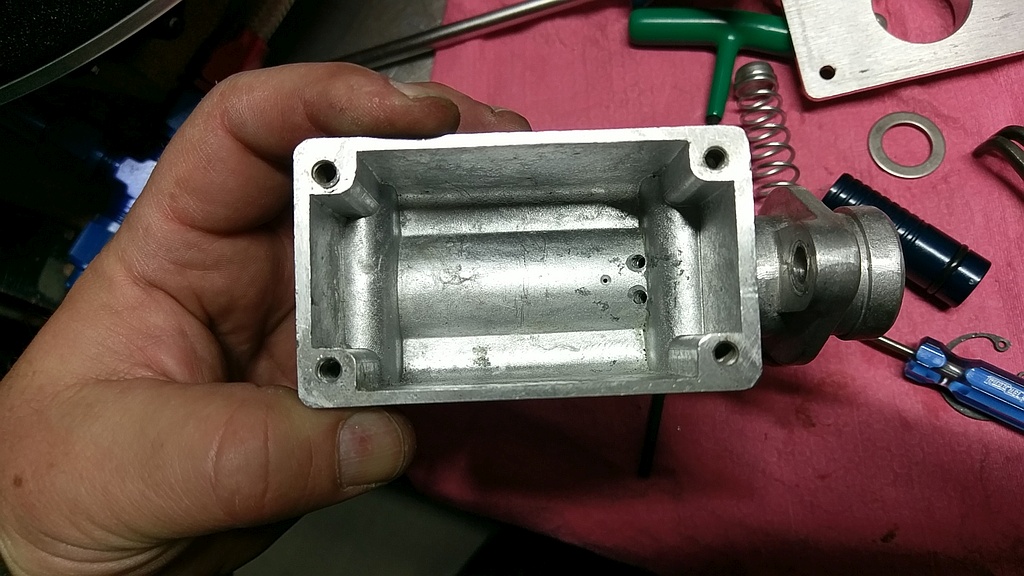

The CNC 702 3/4" Master Cylinder

These are a well made part featuring a stainless steel insert. Not light like the Tilton or Wilwood's but everything is metal and thick. These are used on the Mustang's brake set up. These often find their way on to dune buggies and sand rails. Highly recommend them.

Removing the Master Cylinder Piston

Using the snap ring pliers remove the snap ring. Makes sense... The piston should pop out with the retaining washer.

Close Look at the Piston

This looked very good. After looking for any wear marks or dirt I was beginning to thing that the used master that was in the set was only used for testing or something as it does not look like it has seen any service other then a fill of fluid or possibly they used the wrong sized master and swapped it out. In any case looked good and was happy to not see any marks in the stainless bore either. Once the piston is out you likely will have a rubber piece stuck in the bore.

CNC-702 Lid Removed

With the lid and rubber gasket removed this is what it looked like. Pretty clean except for a bit of dried up fluid.

Removing the Rubber Cap

I used a bit of air to blow it out. I think you could use a non-sharp dowel or something thin to get it. Air seemed the best way to go.

Piston Seal Cap or Whatever...

Not sure what you call this part, but it's on the end of the piston. Don't worry a new one comes with the rebuild kit if you botched it up.

Piston Assembly

Here is the piston assembly and how it goes together. You can also see the large opening washer that is held in by the snap ring in the upper right.

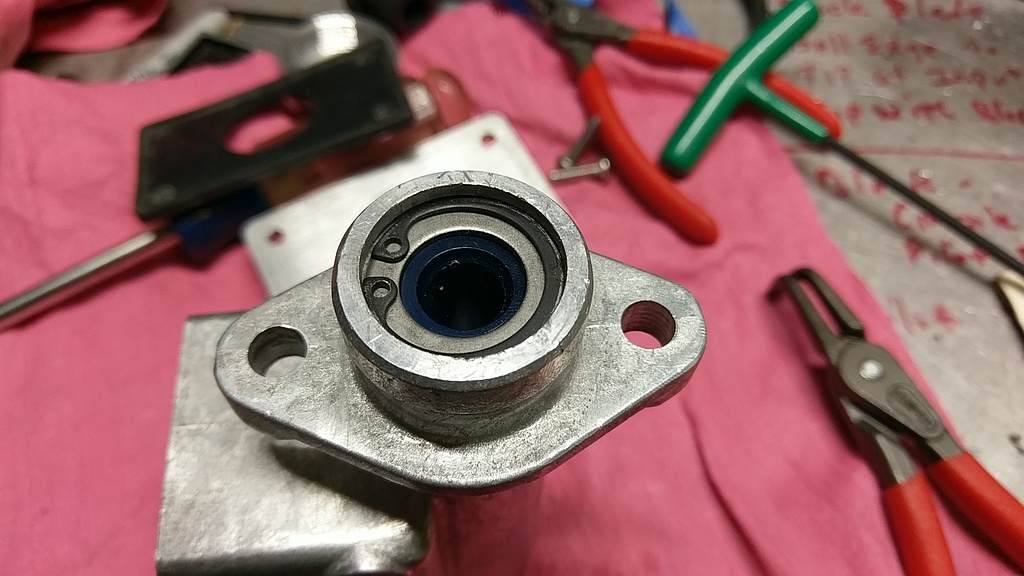

Push Rod Side with Snap Ring

This is the push rod side of the master. You can see that the snap ring that must be removed. It's SPRING LOADED so be careful in case it pops out.

Wrong Rebuild Kit

Thinking I had one of these in the tool box, I thought I got lucky. Looked perfect except for one small detail... This was for a slave cylinder and the piston has a different depth center bore then the master cylinder. Oh well. This one was the 907R which is not correct for the master.

Subtle Piston Differences

The pistons that came out of the rebuild kit I had (the 907R) was for a slave cylinder. It has a short bore vs. the one that came out of the master cylinder. So while darn close, not going to work. I ended up waiting for the proper kit even that the removed piston was virtually new.